| Design of dies - Bend forming |

|

| Design of progressive dies capable of complicated bend forming, for instance pins of wire harness, bus bar of connector terminal for automobiles. |

|

|

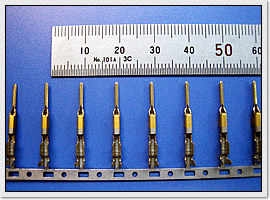

| Pin I |

|

|

| Pin II |

|

|

|

| Design of dies - Fine blanking |

|

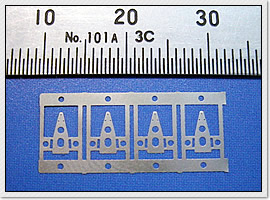

Various types of sheet material are available - metal, stainless, copper, aluminum, ceramic green sheet.

Minimum thickness is 0.0352mm (stainless foil); maximum is 8.0mm (metal sheet for fine blanking) |

|

|

| Stainless Used Steel foil (0.035mm) |

|

|

| Design of dies - Drawing forming |

|

| OSK's progressive and transfer dies are capable of squeezing forming such as cylinder, square cylinder and 3D forming as well as side surface hole processing. |

|

|

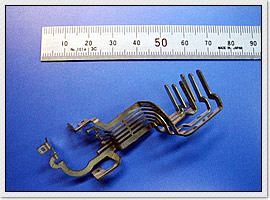

| Slit cutting |

|

|

| Drawing forming |

|

|

|

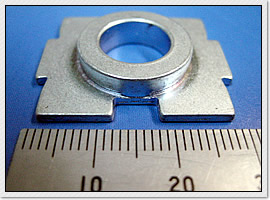

| Design of dies - High precision forging |

|

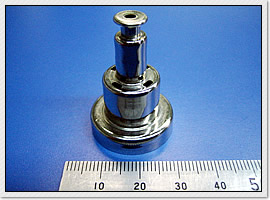

| For the purpose of substantial cost cut, OSK design plate forging progressive dies which can replace conventional cutting, molding, casting, sinter forming production. |

|

|

| High precision plate forging I |

|

|

| High precision plate forging II |

|

|

|

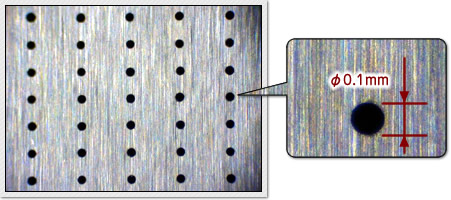

| Electrical Discharge Machining (EDM) |

|

| Possible to make fine holes φ0.1 |

|

|

| EDM |

|

|

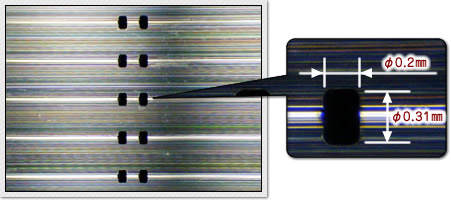

| Wire EDM |

|

| Possible to make fine shapes by using fine wire φ0.05 |

|

|

| Wire cut |

|

|

| High Speed Machining Center |

|

| Reduce steps to produce by 3D grinding. |

|

|

| SKD-11 |

|

|

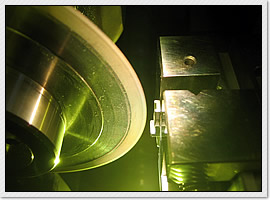

| Profile Grinding |

|

| Guarantee parts accuracy by precision profile grinding |

|

|

| Profile grinding |

|